"Field cutting of metal panels, particularly at framed openings, is an acceptable alternative to cutting in a manufacturing facility. Most metal panel manufacturers, in fact, will allow (and expect) installers to cut metal roofing and wall panels on-site, but in order for the panels to be protected from damage and ensure the longevity that metal panels are known for, there are certain do’s and don’ts when it comes to recommended cutting methods, tools, and even the location where the cutting is done. "

March 4, 2021

by Star Building Systems

Methods, tools and even the location of where the cutting is taking place can all affect the performance and appearance of the metal panels being cut on-site, so it is important to follow certain protocols and guidelines. Best practices include:

The first thing to note is that metal roof and wall panels are usually fabricated from Galvalume®-coated steel coil because of its longevity and protective properties. Manufacturing facilities employ tools and methods to cut the coated metal coil, which helps protect the cut edge from deterioration (ex.: rust and corrosion). Also, during fabrication, the coated metal is cut to length either by shearing while flat before entering the roll former, or by the use of a profile shear as the panels exit the roll former. These methods serve to “wipe” the Galvalume coating across the cut edge of the metal panels, providing superior cut-edge protection from corrosion.

If field cutting is needed once the panels arrive on-site, it is important to similarly protect the edge of the steel from corrosion by following recommended strategies and protocols.

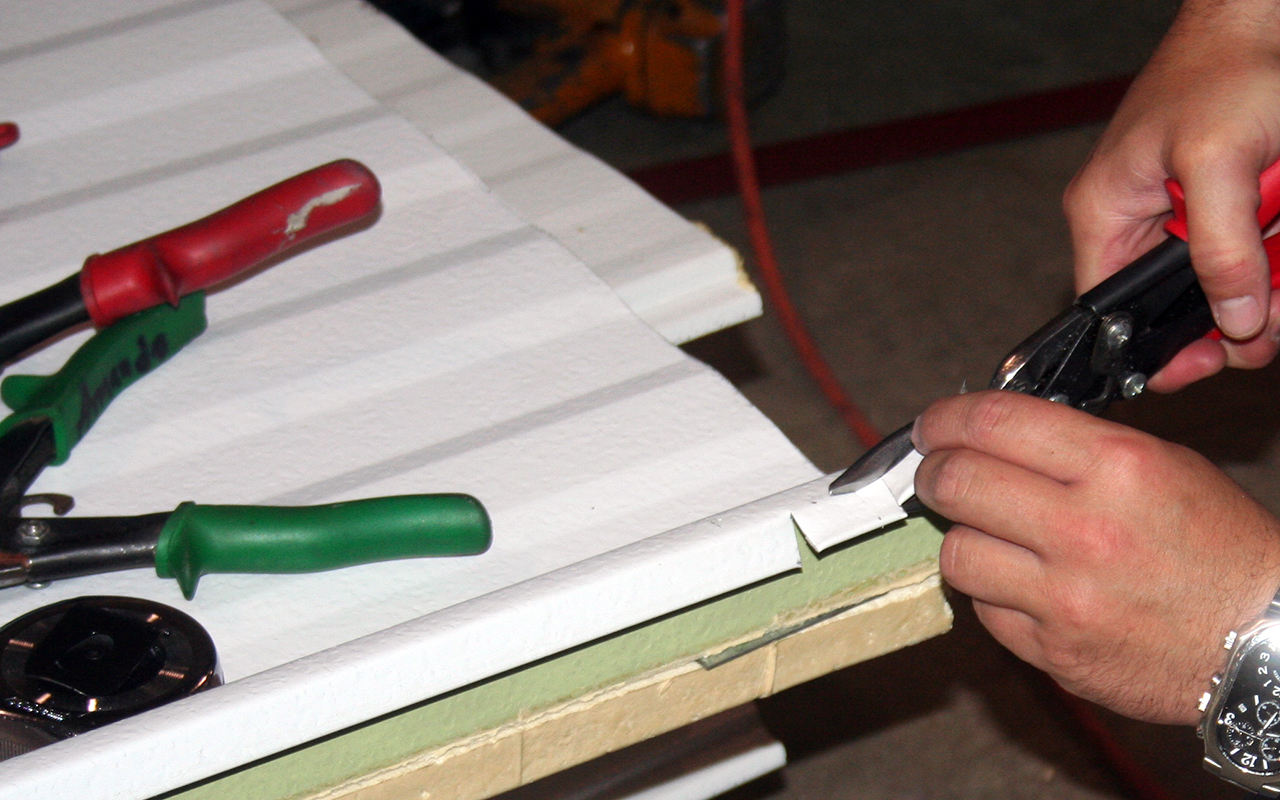

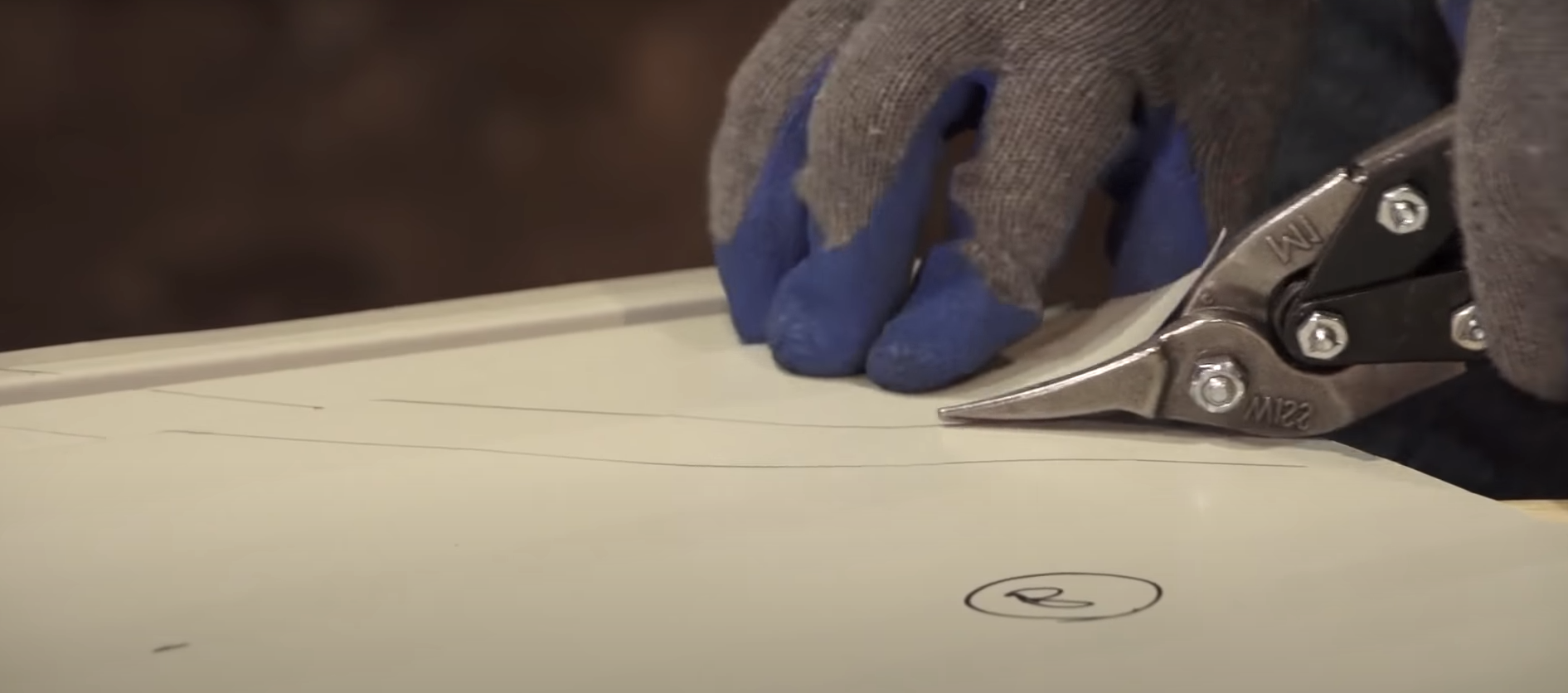

The old saying that you only get out what you put in holds true for metal panel cutting. Using the right tools (in the right way) can ensure good results, while the wrong tools can result in an array of unfortunate and long-lasting problems, such as rust and rust stains, voiding of warranties, and compromised building service life. Among the features of good tool choices for field-cutting metal panels are those that will wipe the Galvalume coating, are cool, and will protect edges. Recommended tools include the following:

typically used when making lengthier cuts along the steel (ex.: cutting a wall panel at a corner or at a door opening). Electric shears will take a ¼” strip of metal out of the panel during the cutting process. This process tends to leave both sides of the panel smooth and flat along the cut. Electric shears will also wipe the Galvalume® coating over the cut edges to offer protection.

STOP! Do not use these tools.

Equally important as using the right tools is NOT using the wrong tools. When cutting metal panels on-site, never use the following tools—torches, reciprocating saws, hacksaws and grinders—as they will melt the Galvalume® coating, causing edge rust just like an abrasive blade would.

In conclusion, using the right tools and following the recommendations provided by the metal panel manufacturer when cutting metal in the field will help ensure that the panels are protected from damage, while using the wrong tools can result in rust, rust stains, corrosion, and the voiding of warranties. To find out more about the best practices and recommendations for on-site cutting and installation of metal panels contact your local Star Building Systems representative.

Become part of the powerful Star network. We invest in builders who understand the value of results and provide support that develops strong relationships between you and the entire Star team.

Your building is the cornerstone of the community where people live, work and play. Find a local Star Authorized Builder and let us help you bring your vision to life.