October 5, 2016

by Star Building Systems

In my last guest post on updates to building envelope code requirements, I briefly touched upon the important new role that air barriers play in the latest IECC 2015 and ASHRAE 90.1.2013 energy codes. I received a lot of questions about air barriers from the last post, so I thought it would be a good idea to take some time to elaborate on a topic that is becoming increasingly important in code compliance for building envelopes. Let’s dive in.

An air barrier is a material or system of materials designed to reduce uncontrolled air leakage and air infiltration through a building’s thermal envelope. Remember that the thermal envelope separates conditioned space and outdoor air. An air barrier can technically be comprised of different types of material and/or coatings, such as polyolefin.

When an air barrier is assembled with a number of materials, it becomes an air barrier system. As the Air Barrier Association of America (ABAA) notes, an air barrier system essentially “wraps” the building shell and ensures that it protects the building from the effects of air leakage.” Air barrier systems provide a barrier to not only water vapor, but also to “pollutants entering either the building or the building enclosure, such as suspended particulates, dust, insects, smells, etc.”

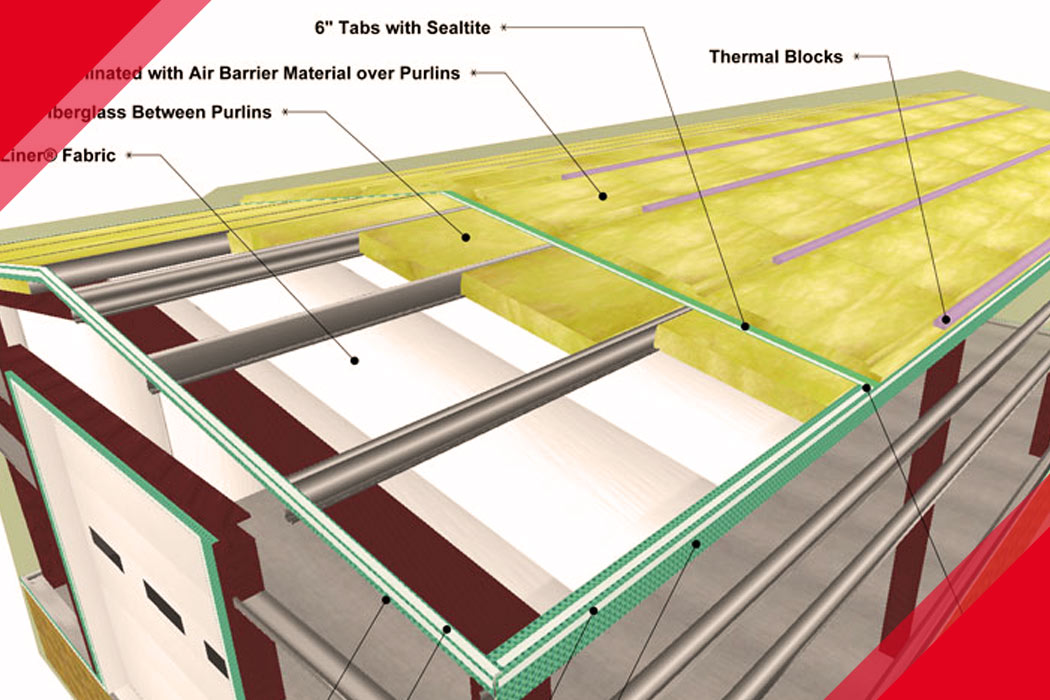

Pictured: MaxTight™, Therm-All’s patented air barrier system

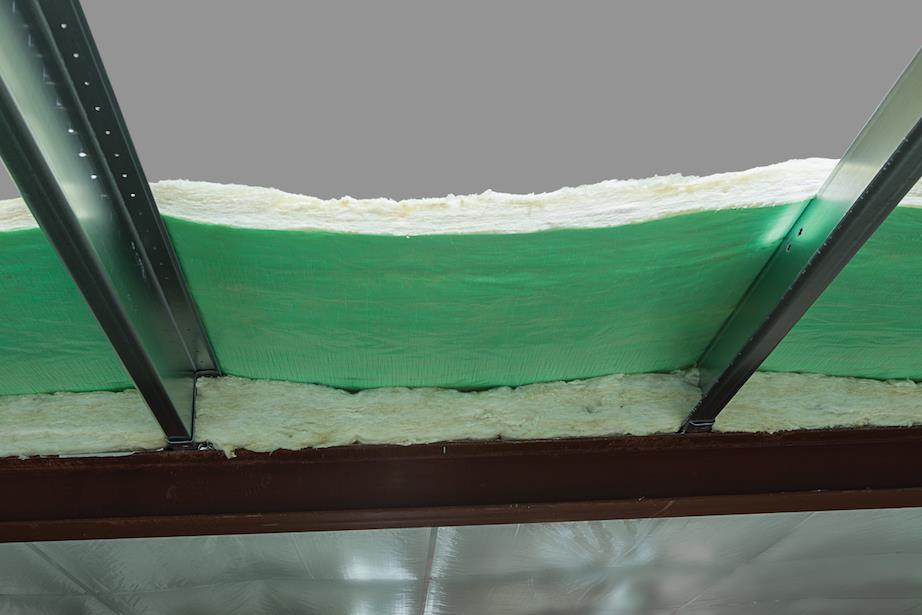

The image above is a good example of an air barrier system. The green material is the actual air barrier which, in this case, is made up of a cross-woven non-perforated building wrap with a breathable polyolefin coating. As you can see, the air barrier is part of a double layer High-R Liner System (Ls), which includes liner system components (fabric, banding) and two layers of fiberglass, with the air barrier laminated to the second layer of fiberglass.

An air barrier can be placed on the interior side, exterior side, somewhere within assemblies composing the envelope, or any combination thereof. In the picture above, the air barrier is placed within the assembly, which adds a lot of value to the overall system, and the building itself. When placed within the assembly, the air barrier is protected from damage by trade workers who cannot poke holes in it as they might do in exposed vapor retarders. This means that the system provides a fully sealed airtight envelope.

First, a building designer must identify the air barrier. A vapor retarder can be designated as both an air barrier and as a vapor retarder. If a designer chooses to use an air barrier separate from the vapor retarder, the air barrier then cannot be a vapor retarder and must be a breathable barrier. In essence, the air barrier design needs to be amped up a notch to go further than a vapor retarder if it’s appropriated separately. If the air barrier is placed within the thermal envelope, the perm rating should be between 15 and 25 perms. This allows water vapor, a gas, to carry its moisture through the air barrier and not trap moisture. A true vapor retarder should be between .09 and .02 perms.

Both IECC 2015 and ASHRAE 90.1.2013 now require buildings to have an air barrier in the thermal envelope, and to be indicated in drawings. The first mention of air barriers was actually in IECC 2009. ,Consequently, the next few code cycles made air barriers mandatory requirements. The air barrier is also a checklist item on a COMcheck™ report. However, remember that blower door testing is not required unless the building designer chooses to do so. Blower door testing is a compliance option that tests air leakage of the entire building as a whole. You can read more about air barrier compliance options in a post I wrote for my “Code Man” blog.

As the future of code cycles change, the air barrier requirement will only increase in terms of required performance. This is a good thing for the metal building industry, as new requirements propel new innovations. If you have questions about any of the information discussed in this post, click on this link and fill out the form at the bottom of the page and I’ll get back to you within 48 hours.

Become part of the powerful Star network. We invest in builders who understand the value of results and provide support that develops strong relationships between you and the entire Star team.

Your building is the cornerstone of the community where people live, work and play. Find a local Star Authorized Builder and let us help you bring your vision to life.